By

Sarah Johnson, CLM, CSSBB

Director of Quality and Process Development

It is a fundamental truth of the universe that variation is inherent in all things. You may not have ventured this way to learn universal truths, but here we are. Why should you care? In the natural world, variation can be a wonderful and beautiful thing. In the manufacturing world, however, variation is directly tied to the Big Three – quality, cost, and delivery. Reducing variation often leads to lower costs, higher quality, and shorter lead times. The opposite is also true. So how does variation affect you? It can raise your costs, lower your quality, and lengthen your lead time.

What can you do about it? Here’s where it gets interesting. As a designer or anyone who wants something manufactured, understanding the concept of variation, and determining how to allow for it before it touches the factory floor gives you a huge return on investment. Small costs upfront can lead to huge savings down the road.

One of the best ways of working with the variation instead of against it is to understand the Voice of the Process. Any process has its own distribution of variation – the level it can perform to given its inputs. Before determining a specification, understand what the process is capable of producing. Let’s say the following curve represents the distribution of the output of a given process:

Figure 1: The Variation of the Process

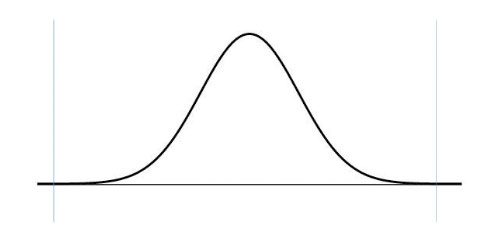

If your upper and lower specifications are as noted by the blue lines below, you will be in great shape! The variation of the process is well inside what your product needs to perform. You will have high yield and very low scrap.

Figure 2: Specifications Wider than the Process Variation

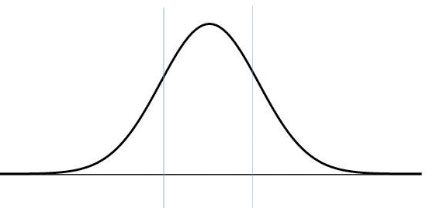

But what if your specification is here?

Figure 3: Specifications Narrower than the Process Variation

That’s a problem. This will cause high levels of rework and poor quality, which will then lead to higher costs and late deliveries. In this scenario, a technician could see that a component on a PCBA “failed” but no matter how much digging they do, they don’t find anything wrong. That’s because there may be nothing wrong – the specifications are inside the capability of the process and the “failed” component is just inside the normal variation of the process. The only recourse may be for the technician to randomly change out components until they happen on one that is in the right part of the distribution. Clearly, this is not ideal.

What if Figure 3, above, is where you find yourself and you need the specification to be that tight compared to the distribution? If it’s a component issue, a design engineering change may need to be made. If it’s a process issue, that’s where process engineers get to work figuring out how to reduce that variation.

It is crucial to consider this concept during a design phase. If specifications are determined without considering the process capability, how is the relationship between the two going to affect the yield? It puts us in a place no one likes to be – ignorant of the expected outcome.

At Vergent Products, all our Process and Quality Engineers are trained in these concepts, and we consider the Voice of the Process compared to specification requirements during our New Product Introduction processes. Our goal is to prevent problems before they occur. Using statistics, we can predict the total yield of a product before we ramp up to volume. We can even suggest specifications that will allow your product to have a high yield. This allows us to proactively address issues before the cost is incurred and is one of the reasons our clients keep coming back.